住友理工的电池垫片,继续用于丰田新"MIRAI"

自 2000 年代初以来,住友理工开始开发用于燃料电池 (FC) 的产品,以安装在燃料电池汽车 (FCEV) 中。2008年,我们开始与丰田汽车公司共同开发"密封件"。继2014年丰田发布的FCEV"MIRAI"(初代车型)之后,2020年的新"MIRAI"继续采用完成的橡胶密封件"电池用垫片"。MIRAI被称为以氢为能源、行驶时只排放水的终极环保汽车,其动力源是堆叠了300多个电池的FC电堆。通过保持氢气、氧气和冷却水的流动路径,并开发具有高密封可靠性的电池垫片,我们实现了FC堆的高性能。

在新的"MIRAI"中,我们引入了一种新的构造方法,并成功地使垫片无偏差,为进一步的小型化和轻量化做出了贡献。此外,通过融合在从低温到高温的宽温度范围内实现长期密封性能的高性能橡胶和通过开发反渗透等产品培育的精密加工技术,确保了 FC 的长期可靠性。汽车用振动橡胶。我是。今后,我们将继续在不断变化的汽车市场中灵活应对客户的需求,解决各种社会问题,为实现对人类和地球环境友好的下一代汽车社会做出贡献。

Sumitomo Riko's gaskets for cells are continued to be used Toyota's new "Mirai".

Sumitomo Riko first started developing products for FC in fuel cell electric vehicles ( FCEV ) in early 2000s. In 2008, the company started joint development with Toyota Motor Corporation of "seal components", the basis of the "cell gaskets". Toyota has used the complete rubber sealing component "cell g asket" in the FCEV" Mirai" (first model) from the time of its launched in 2014 and have continued its use in the 2020 "Mirai" new model.

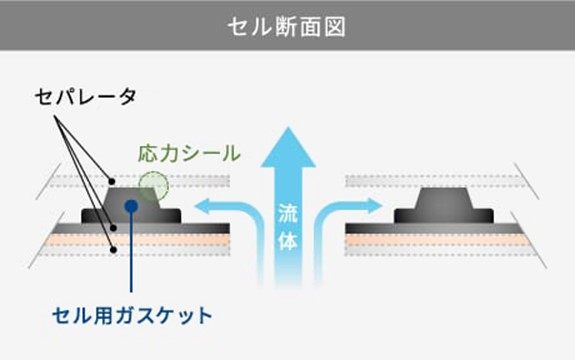

The Mirai is fueled by hydrogen and produces only water as its exhaust, making it extremely ecological. Its power source is an FC stack of 300 or more cells. With separate channels for hydrogen, oxygen and cooling liquid, and the development of cell gaskets with highly reliable seal, the FC stack has achieved a high level of performance. The new Mirai has succeeded in the development of a smaller and lighter burr-less gasket through the introduction of new manufacturing methods.

Furthermore, we fused our precision processing technology built up through developing products such as automobile a nti-vibration rubber, and the high-performance rubber, which has long-terms ealing properties across a wide range of temperatures, thereby ensuring the long-term reliability of FCs.

Sumitomo Riko is committed to flexibly responding to the needs of our customers in the evolving automobile market, while solving issues in society, and contributing to the production of people and earth-friendly vehicles.

电池垫片

防止氢、氧和水泄漏到 FC 堆内部的橡胶密封件。从零度以下,在100°C以上的宽温度范围内表现出高密封性能,有助于FCEV的长期安全性和高效发电性能。

The FC stack contains hydrogen, oxygen and rubber sealing material to prevent water from leaking. The material is capable of sealing in temperatures ranging from sub-zero to 100℃ or higher and it contributes to the long-term stability and highly efficient power generation of FCEVs.

For example, a rubber composition including the following contents of (A) to (D) is capable of crosslinking at a low temperature, and is well-suited in terms of high adhesive reliability and sealability of the crosslinked item. (A) One or more rubber components selected from a group consisting of ethylene-propylene rubber (EPM), ethylene-propylenediene rubber (EPDM), acrylonitrile-butadiene rubber (NBR), and hydrogenated acrylonitrile-butadiene rubber (H-NBR); (B) a crosslinking agent selected from organic peroxides of which a 1-hour half-life period temperature is lower than or equal to 130°C; (C) a crosslinking auxiliary agent; and (D) an adhesive component formed of at least one of a resorcinol compound together with a melamine compound and a silane coupling agent.

艾邦氢能产业链通讯录,目前有2200人加入,如亿华通、清极能源、氢蓝时代、雄韬、氢牛、氢璞、爱德曼、氢晨、喜马拉雅、明天氢能、康明斯、新源动力、巴拉德、现代汽车、神力科技、中船712等等,可以按照标签筛选,请点击下方关键词试试

资料下载:

艾邦氢能产业链通讯录,目前有2200人加入,如亿华通、清极能源、氢蓝时代、雄韬、氢牛、氢璞、爱德曼、氢晨、喜马拉雅、明天氢能、康明斯、新源动力、巴拉德、现代汽车、神力科技、中船712等等,可以按照标签筛选,请点击下方关键词试试

资料下载: