快速增长的电动车市场要求更经济地生产更多组件,例如燃料电池。

The rapidly growing demand for electromobility requires the economical production of large quantities of components – for example for fuel cells.

在目前的一个研究项目中,法因图尔小组、瑞士西北科学大学和阿尔高技术中心正在开发一种经济的成型工艺,用于燃料电池金属双极板的大量生产。

In a current research project, the Feintool Group, the University of Applied Sciences Northwestern Switzerland and the Hightech Zentrum Aargau are developing an economical forming process for the high-volume production of metallic bipolar plates for fuel cells.

燃料电池提供了一个有效的替代大型电池的市场。当需要进行长距离和短程加油时尤其如此——例如可在商用车辆、公共汽车和火车上作为柴油发动机的替代品。

然而,燃料电池目前仍过于昂贵,无法广泛使用。每个燃料电池核心典型的300 - 400个双极板,也就是所谓的堆栈,占制造成本的一半以上。

Fuel cells offer a valid alternative to large batteries in electric mobility. This is especially true when a long range and short refueling stops are required – for example in commercial vehicles, buses and trainsets as a diesel engine substitute.

However, fuel cells are currently still far too expensive for widespread use. The typical 300 – 400 bipolar plates of the heart of each fuel cell, the so-called stack, account for more than half of the manufacturing costs.

因此,人们正在寻找一种新的生产技术,以确保该技术的市场开拓能力。目前燃料电池系统主要使用石墨双极板,但金属双极板由于能量密度低、制造成本高,将被取代。然而,在金属双极板的生产中,还需要解决各种技术难题。

Therefore, a new production technology is being looked for to ensure the marketability of this technology. Currently, mainly graphite bipolar plates are used in fuel cell systems, but these are to be replaced by metallic bipolar plates due to their low energy density and high manufacturing costs. However, various technical challenges still need to be solved in the production of metallic bipolar plates.

实际上,我们寻求一种能使非常薄的钢板以要求的高精度制造出来的生产工艺。法因图尔集团在精密冲裁工艺的冲压和工具技术方面具有多年的经验。这是当前项目的起点,旨在开发一种比液压成形或传统冲压成形相结合的替代工艺更精确、更经济的生产技术。

In particular, a production process is sought that allows the very thin plates to be manufactured with the required high precision. The Feintool Group has many years of experience as a technology leader in both press and tool technologies for the fineblanking process.

This was the starting point for the current project, which aims at developing a production technology that is both more precise and more economical than alternative processes such as hydroforming or conventional punching combined with forming.

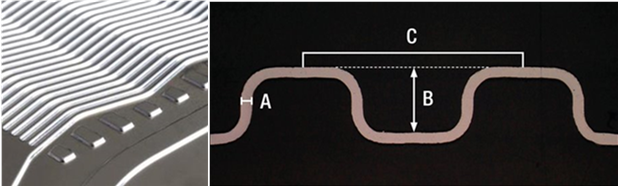

微型精密要求

Micro-precision required

稳定、创新的制造流程

A stable, innovative manufacturing process

新开发的工艺能够生产出形状经过优化、精密的阴极和阳极板几何形状,使双极板流场内的气体通道具有更好的轮廓。这转化为更好的电接触,更低的内阻,从而更高的燃料电池效率。

The newly developed process enables the production of shape-optimized, precise cathode and anode plate geometries that allow better contoured gas channels within the flowfield of the bipolar plates.

This translates into better electrical contact, lower internal resistance, and thus higher fuel cell efficiency.

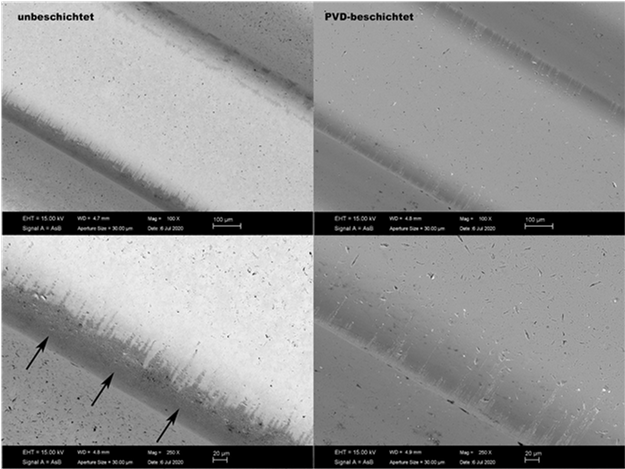

然而, 只有在刀具制造、刀具几何形状、表面技术和冲压技术等各种制造技术创新的复杂相互作用下,才有可能实现这一突破——并将有助于燃料电池未来的成功,作为电动汽车替代驱动概念的一部分,以及可再生能源的进一步应用。

However, it was only the complex interplay of various manufacturing technology innovations in tool making, tool geometry, surface technology and press technology that made this breakthrough possible –and will contribute to the future success of fuel cells as part of alternative drive concepts in electromobility and further applications of renewable energies.

原文始发于微信公众号(Feintool法因图尔):法因图尔关于新型的高精度双极板的研发制造

艾邦氢能产业链通讯录,目前有2200人加入,如亿华通、清极能源、氢蓝时代、雄韬、氢牛、氢璞、爱德曼、氢晨、喜马拉雅、明天氢能、康明斯、新源动力、巴拉德、现代汽车、神力科技、中船712等等,可以按照标签筛选,请点击下方关键词试试

资料下载:

艾邦氢能产业链通讯录,目前有2200人加入,如亿华通、清极能源、氢蓝时代、雄韬、氢牛、氢璞、爱德曼、氢晨、喜马拉雅、明天氢能、康明斯、新源动力、巴拉德、现代汽车、神力科技、中船712等等,可以按照标签筛选,请点击下方关键词试试

资料下载: